During start up the control box sends electricity to the pump motor through the start circuit.

Franklin electric well pump control box troubleshooting.

Remove the screw at the bottom of the pump control cover and lift it off the box to disconnect it.

Troubleshooting submersible well pumps 101.

You can also check out our video titled how to troubleshoot a qd control box on the rc worst youtube channel or give our experts a call at 855 329 4519.

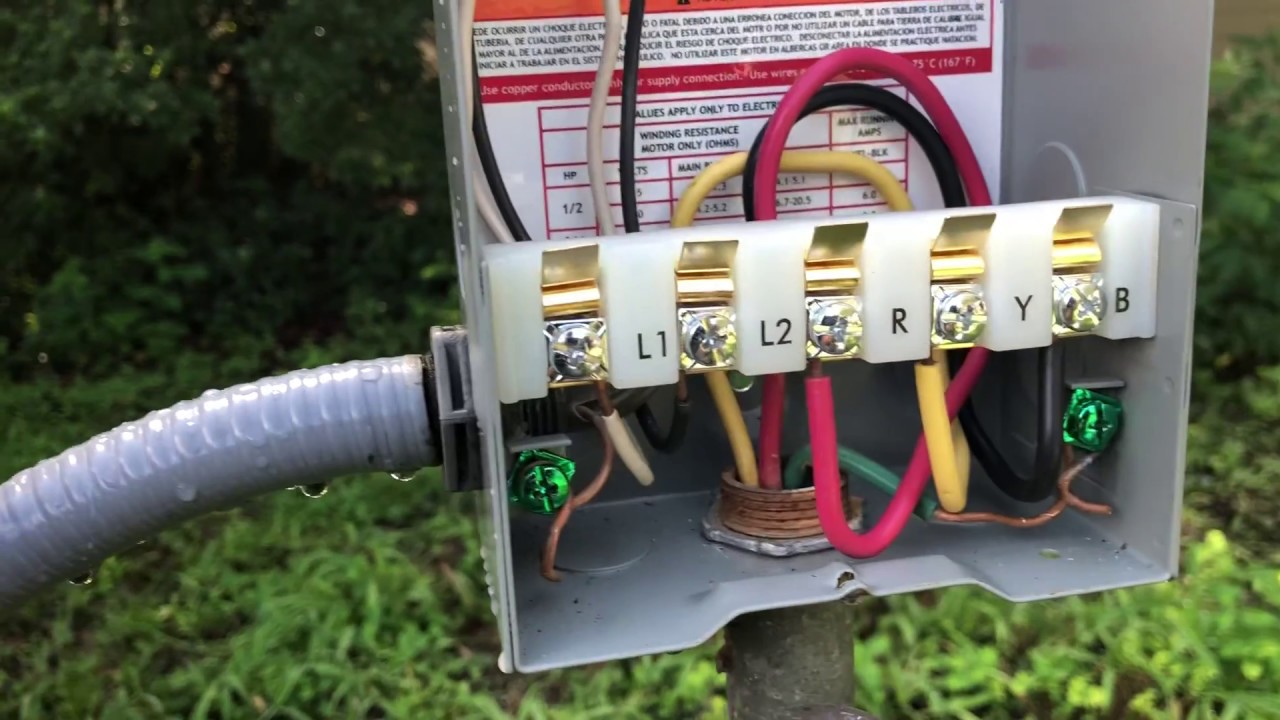

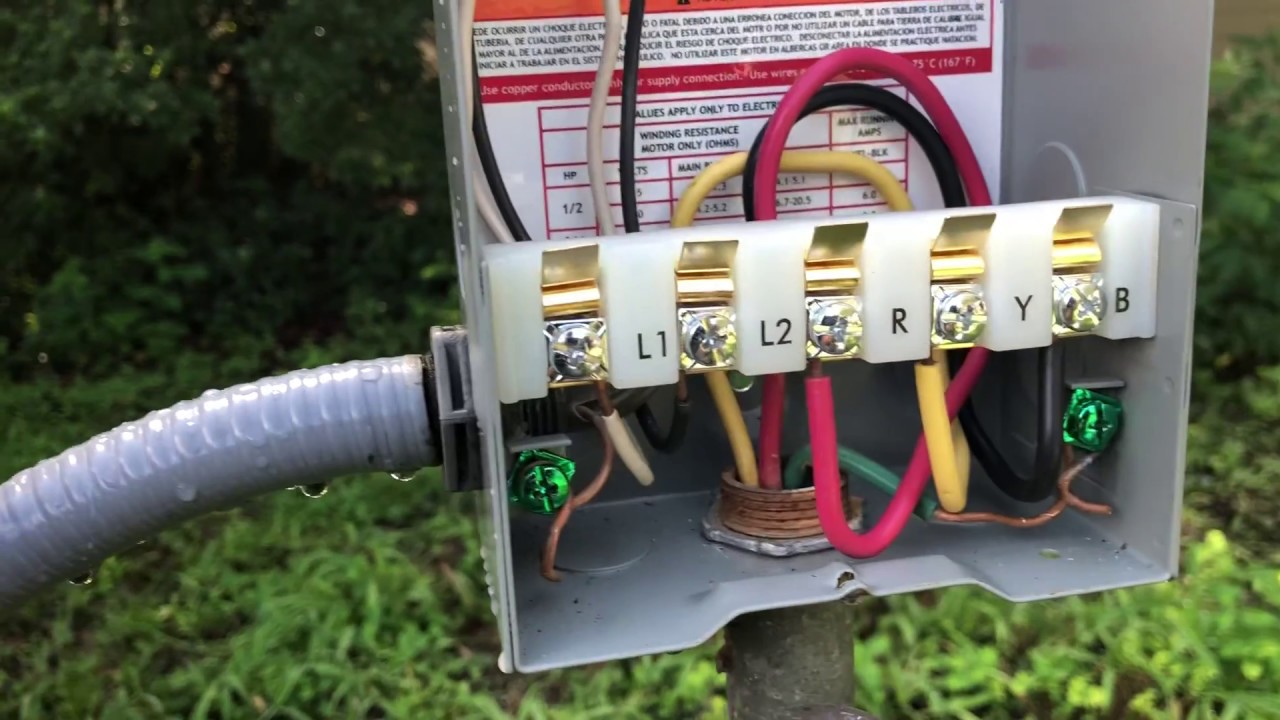

Testing a franklin electric qd quick disconnect box.

Well pump troubleshooting and diy repair.

Standard and deluxe boxes are for 1 hp 15 hp single phase water systems that use standard heavy duty pressure switches level switches or other pilot devices.

Our dedicated support teams will make sure our business isn t what slows yours down.

Subscribe ring the bell.

That s why franklin electric has your back every step of the way.

Once the pump motor reaches operational speed the control box switches the electrical feed to the run circuit.

If this setting was reduced below maximum value increase verify motor pump ratings and match to motor pump settings on drive dip switch or wi fi verify motor connections.

Figure out how to fix your well yourself.

Incorrect motor or pump settings motor may be running backwards gulping water at pump inlet verify maximum frequency setting.

It won t start the well pump and you won t have water so testing the switch is your first step.

Full troubleshooting guide can be found in the franklin electric aim manual.

Chris quickly shows you how to test the relay that comes in franklin electric control boxes 33 to 15 hp.